Avocado and Tallow Shampoo BarsAvocado and Tallow Shampoo Bars

Your folders

Your folders

Total: 2960

Servings: 1010

Ingredients

Export 6 ingredients for grocery delivery

Instructions

Step 1

Ensure you can work distraction free for a couple of hours. No kids or pets around while you are making soap! Work in a well ventilated area. Wear your protective gear!

Step 2

Weigh out all ingredients in separate containers. Use only containers that are non reactive to lye. Ceramic, heat proof glass, stainless steel, and thick plastic are great. Absolutely no aluminum products.

Step 3

Add lye to the water. "Snow falls on the lake"

Step 4

Stir with a stainless steel spoon until the lye has dissolved. Do not inhale the fumes produced during this process.

Step 5

Set aside in a safe place to cool.

Step 6

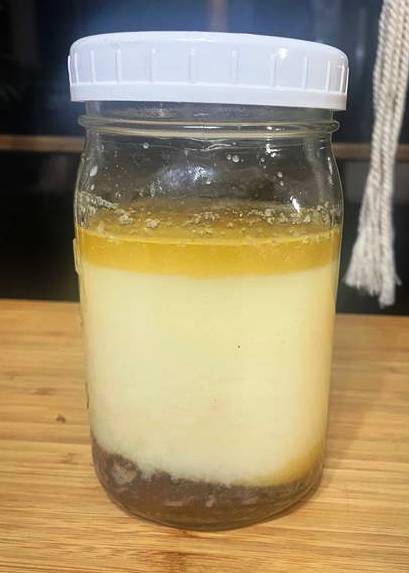

Combine all the oils and fats into a stainless steel pot or bowl. Heat over low-medium heat until all solids have melted.

Step 7

You want the lye solution and fats to be within ten degrees of each other before combining. A good temperature range is between 110-140. If the lye solution is still too hot (over 140F) allow it to cool further.If the oils are significantly cooler than the lye when they are fully melted, keep it over low heat until the lye has cooled more.

Step 8

Once the lye solution and oils are under 140F and within ten degrees of each other, add the lye solution to the oils. Pour over the shaft of your immersion blender to reduce air bubbles.

Step 9

Burp your immersion blender to release any air bubbles trapped under the bell. Pulse for a few seconds, then stir. Repeat until the mixture has fully emulsified and reached light trace. Trace is when the batter begins to thicken.

Step 10

Add in any essential oils, if using. Whisk those in until fully incorporated.

Step 11

Pour the soap batter into the mold. Wiggle it around and bang on the counter or floor to release any air bubbles.

Step 12

Decorate the top as desired.

Step 13

Spritz with isopropyl alcohol, if desired, to reduce the chances of soda ash formation.

Step 14

Optional. Wrap the mold in a towel or blanket to encourage the soap to go through a gel phase.

Step 15

Set aside in a safe place for 24-48 hours.

Step 16

Unmold your soap and cut into one inch wide bars.

Step 17

Set aside in a well ventilated area out of direct sunlight for 4-6 weeks before use.

Step 18

Ensure you can work distraction free for a couple of hours. No kids or pets around while you are making soap! Work in a well ventilated area. Wear your protective gear!

Step 19

Weigh out all ingredients in separate containers. Use only containers that are non reactive to lye. Ceramic, heat proof glass, stainless steel, and thick plastic are great. Absolutely no aluminum products.

Step 20

Add lye to the water. "Snow falls on the lake"

Step 21

Stir with a stainless steel spoon until the lye has dissolved. Do not inhale the fumes produced during this process.

Step 22

Set aside in a safe place to cool.

Step 23

Combine all the oils and fats into a stainless steel pot or bowl. Heat over low-medium heat until all solids have melted.

Step 24

You want the lye solution and fats to be within ten degrees of each other before combining. A good temperature range is between 110-140. If the lye solution is still too hot (over 140F) allow it to cool further.If the oils are significantly cooler than the lye when they are fully melted, keep it over low heat until the lye has cooled more.

Step 25

Once the lye solution and oils are under 140F and within ten degrees of each other, add the lye solution to the oils. Pour over the shaft of your immersion blender to reduce air bubbles.

Step 26

Burp your immersion blender to release any air bubbles trapped under the bell. Pulse for a few seconds, then stir. Repeat until the mixture has fully emulsified and reached light trace. Trace is when the batter begins to thicken.

Step 27

Add in any essential oils, if using. Whisk those in until fully incorporated.

Step 28

Pour the soap batter into the mold. Wiggle it around and bang on the counter or floor to release any air bubbles.

Step 29

Decorate the top as desired.

Step 30

Spritz with isopropyl alcohol, if desired, to reduce the chances of soda ash formation.

Step 31

Optional. Wrap the mold in a towel or blanket to encourage the soap to go through a gel phase.

Step 32

Set aside in a safe place for 24-48 hours.

Step 33

Unmold your soap and cut into one inch wide bars.

Step 34

Set aside in a well ventilated area out of direct sunlight for 4-6 weeks before use.

Top similar recipes

Curated for youYour folders

134 views

134 viewsTallow Shampoo Bars

bumblebeeapothecary.com

4.5

(142)

Your folders

178 views

178 viewsTallow Balm

bumblebeeapothecary.com

4.5

(176)

20 minutes

Your folders

266 views

266 viewsTallow Balm

venisonfordinner.com

Your folders

97 views

97 viewsBeef Tallow

homesteadsurvivalsite.com

Your folders

290 views

290 viewsRosemary Mint Shampoo Bars

growforagecookferment.com

Your folders

341 views

341 viewsDog Shampoo

smartschoolhouse.com

Your folders

326 views

326 viewsKIDS SHAMPOO

tbhkids.com

Your folders

687 views

687 viewsBumblebee Apothecary Tallow

bumblebeeapothecary.com

5.0

(5)

6 hours

Your folders

294 views

294 viewsHomemade Shampoo Recipe

wellnessmama.com

Your folders

81 views

81 viewsGrown Alchemist Shampoo

grownalchemist.com

Your folders

376 views

376 viewsHerbal Shampoo Recipe

blog.mountainroseherbs.com

240 minutes

Your folders

207 views

207 viewsCOLOUR PROTECTING SHAMPOO

lorealprofessionnel.co.uk

3.0

(2)

Your folders

317 views

317 viewsHomemade Shampoo Recipe

wellnessmama.com

Your folders

257 views

257 viewsInstant Pot Beef Tallow

girlcarnivore.com

5.0

(13)

60 minutes

Your folders

319 views

319 viewsDIY Whipped Tallow Balm

thehomesteadingrd.com

Your folders

114 views

114 viewsBumblebee Apothecary Tallow Soap

bumblebeeapothecary.com

4.5

(66)

Your folders

103 views

103 viewsDIY Tallow Anti-Aging Face CreamDIY...

sheneedscoffee.com

Your folders

168 views

168 viewsShine Shampoo – Curlsmith EU

eu.curlsmith.com

Your folders

291 views

291 viewsDetox - Shampoo - Grown Alchemist

grownalchemist.com